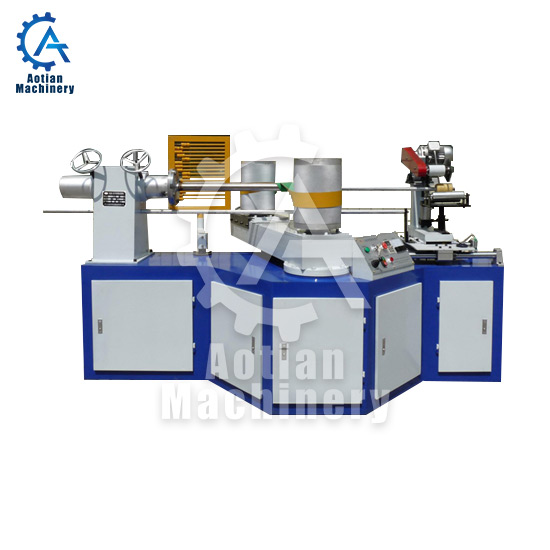

Name: LS– L200 intelligent CNC spiral paper tube machine

Reel diameter: 20–120mm

Coil speed: 3-16m/min

Roll paper layer number: 3—16layers

Paper tube wall thickness: 1—10mm

Host power: 7.5KW

Host specifications: 2600*1700*1600

Power supply: 380V

1.More than 80 function Settings, arbitrary setting of machine operation

2.Glue on either side or both sides

3.Automatic cutting and automatic tube dropping

4.Infrared + host automatic speed change makes the tube length more accurate (error 1-2mm)

5.Automatic synchronous speed change and automatic return when cutting

6.Digital display with head Angle adjustment (optional)

7.Frequency conversion speed control can save 30-60% of electricity than ordinary electromagnetic speed control

8.Electric heating drying device can be added

9.Paper break * glue break automatic stop protection (optional)

10.Ultra-low noise. 65 decibels

11.Stainless steel plastic box + polypress rubber knife, durable

12.Single round knife active cutting, more flat incision, more stable performance

| Reel diameter | 20--120mm | Roll paper layer number | 3—16layers |

| Coil speed | 3-16m/min | Paper tube wall thickness | 1—10mm |

| Transmission mode | Automatic tensioning anti-trip chain transmission | Control form | multi point operation panel |

| Winding head | two head single belt | operators | two |

| Gluing method | Single side or double side gluing | Reel fixed | clamping + flange two-way lock |

| Cutting mode | Single round knife synchronous automatic cutting | Fixed length mode | Infrared precise length |

| Host power | 7.5KW | Host speed ratio | WPO 1:30 |

| Auxiliary power | 0.37KW+0.37KW | Speed control | computer frequency conversion +PLC |

| Host specifications | 2600*1700*1600 | Power supply | 380Vthree-phase four-wire |

If you have any questions, please fill in the following information, we will reply you as soon as possible