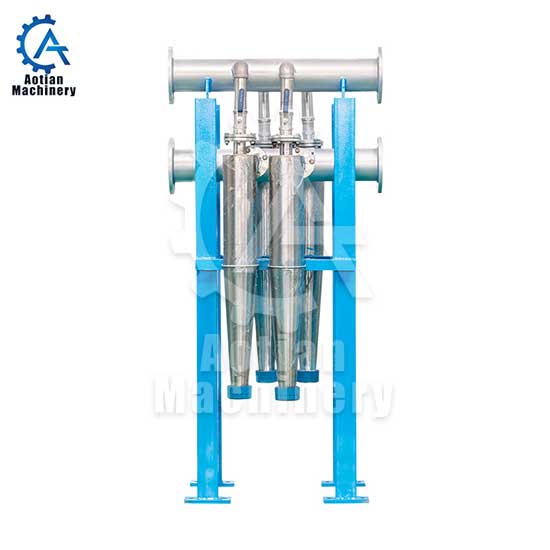

Name: Low Density Cleaner/Centricleaner

Model: AT400-AT1500

Flow of single Equipmen(L/min): 400-1500

Inlet Consistency(%): 0.3-1.5

Pressure of Inflow Pulp(Mpa): 0.2-0.4

Diameter Of Deslagging Outlet: 4-18

In pulping and papermaking process, how much content of impurities in pulp has direct impact on the quality of the paper, and how to remove the impurities in pulp, becomes a key problem. It is mainly used to remove heavy impurities in the pulp and some light impurities. In particular, it is the key equipment of waste paper recycling, its use of fiber and the proportion of the impurities, and make the heavy impurities separated from the pulp, achieve the purpose of purifying pulp.This equipment uses widely, not only can be used for high concentration pulp roughing purification, can also be used for paper machine, selection of low consistency pulp purification.

| Name | Low Density Cleaner/Centricleaner | ||||

| Model | AT-400 | AT-600 | AT-800 | AT-1000 | AT-1500 |

| Flow of single Equipmen(L/min) | 400 | 600 | 800 | 1000 | 1500 |

| Inlet Consistency(%) | 0.3-1 | 0.3-1.2 | 0.4-1.2 | 0.4-1.5 | 0.4-1.5 |

| Pressure of Inflow Pulp(Mpa) | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

| Diameter Of Deslagging Outlet | 4--10 | 6--12 | 6--14 | 6--18 | 6--18 |

If you have any questions, please fill in the following information, we will reply you as soon as possible