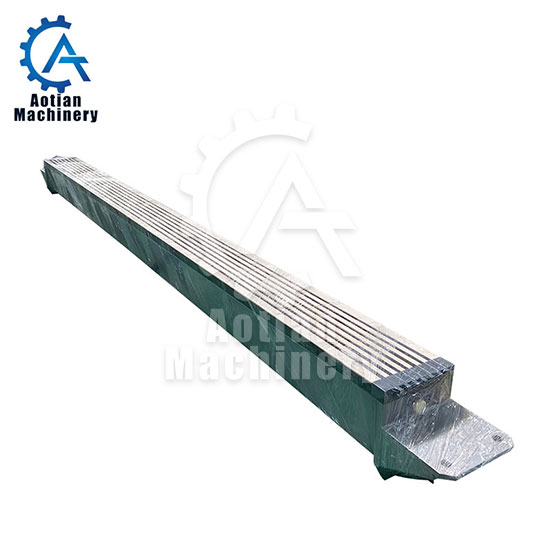

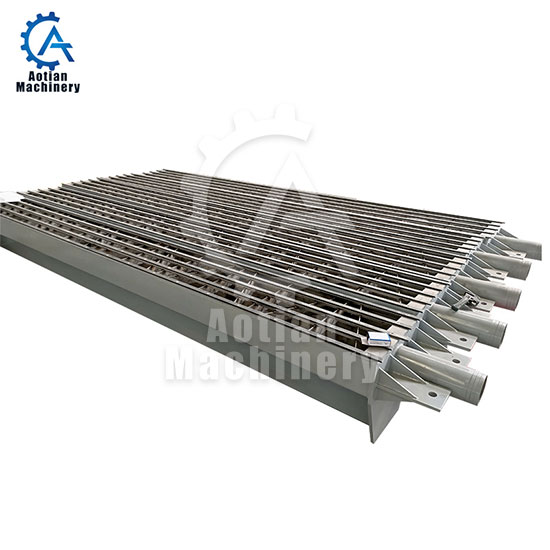

Name: Vacuum Suction Box

Material: UHMWPE / HDPE / PE

Tolerance: +2 -(1-0)

Density: 0.93-0.98g/m³

Water Absorption: <0.01%

Friction Coefficient: <0.09

Injection molding pressure /MPa: 68.9-137.8

It is a kind of traditional vacuum dewatering element of paper machine, the general assembly quantity is 2-11. The vacuum suction box is located at the rear of the fourdrinier table, between the vacuum couch roll and the wet suction box.

The structure design is reasonable and it is a sealed structure. It is sucked by a vacuum pump to make the paper sheet from low-pressure dewater to high-pressure rapid dewater, thereby speeding up the drying of the sheet, enhancing the dewater effect and forming the sheet.

| Material | UHMWPE / HDPE / PE |

| Tolerance | +2 -(1-0) |

| Density | 0.93-0.98g/m³ |

| Water Absorption | <0.01% |

| Friction Coefficient | <0.09 |

| Injection molding pressure /MPa | 68.9-137.8 |

| Shore hardness | (JIS K7215) 60-70 |

| Breakdown strength | 17.7-19.7 |

| Names of Index | Units | Index value | Measured value |

| Hardness | Kg/mm² | HRA=89.5 | HRA=88 convert into HV=1300 |

| Volume density | G/cm³ | 4.08 | 3.8 |

| Coefficient of linear expansion | 1/℃ | (6.9-6.5)*10-6/℃ | (6.9-6.4)*10-6/℃ |

| Zirconia content | % | 99 | 98-99.5 |

| Friction coefficient | 0.005 | 0.007 | |

| Water absorption | % | 0.006 | 0.006 |

| Names of Index | Units | Index value | Measured value |

| Hardness | Kg/mm² | HV=1300 | HRA=88 convert into HV=1300 |

| Volume density | G/cm³ | 3.8 | 3.8 |

| Bending strength | Mpa | 320 | 320 |

| Coefficient of linear expansion | 1/℃ | (6.9-6.5)*10-6/℃ | (6.9-6.5)*10-6/℃ |

| Aluminium Oxide content | % | 98-99.5 | 98-99.5 |

| Friction coefficient | 0.007 | 0.007 | |

| Water absorption | % | 0.006 | 0.006 |

If you have any questions, please fill in the following information, we will reply you as soon as possible